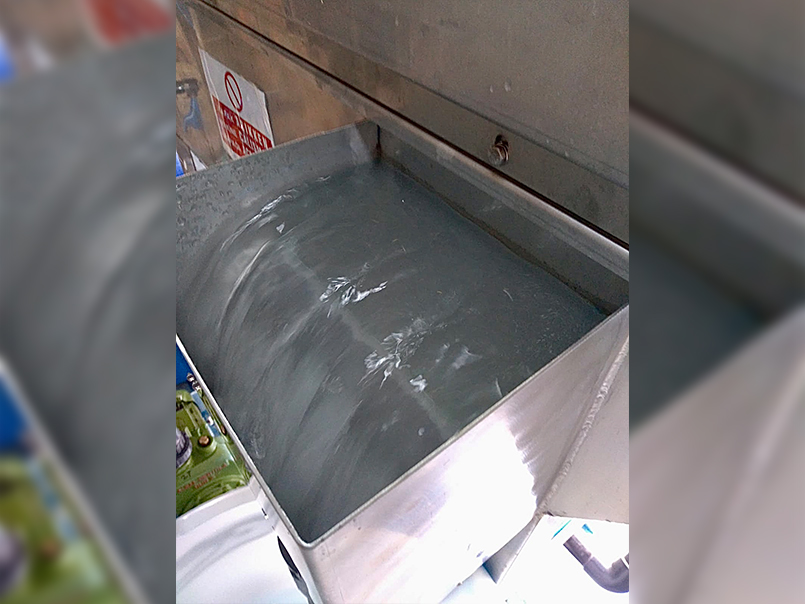

This group of products that is named as dye sludge separation, dyehouse wastewater recycling, or dyehouse wastewater treatment chemicals mainly aims to separate waste dye from water in water-screen and venturi-type paint booths and to use water in closed loop for a long period of time.

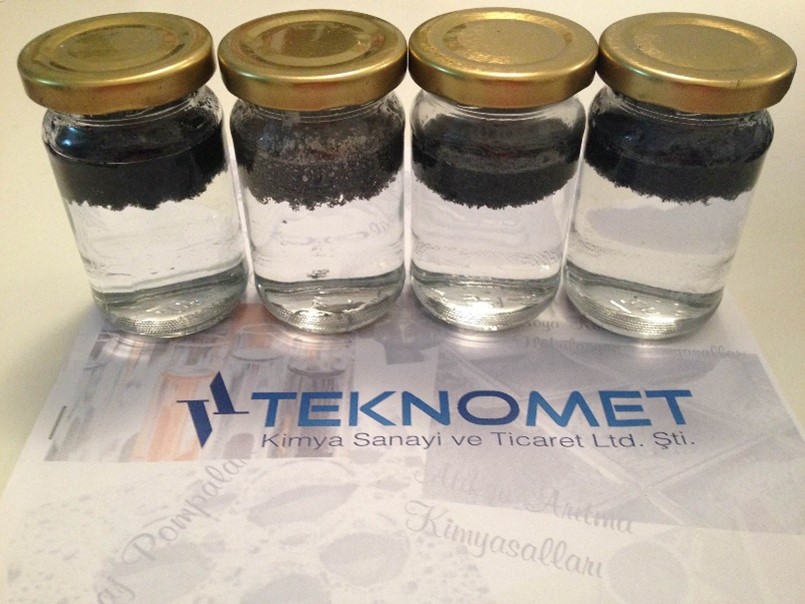

Coagulation of solids with dye coagulant chemicals, release of the adsorbed water, and separation of dye from water are ensured.

This group of products that is named as dye sludge separation, dyehouse wastewater recycling, or dyehouse wastewater treatment chemicals mainly aims to separate waste dye from water in water-screen and venturi-type paint booths and to use water in closed loop for a long period of time. Coagulation of solids with dye coagulant chemicals, release of the adsorbed water, and separation of dye from water are ensured. As a result of the studies on various types of dye and facility, we are able to design and manufacture products that would use ONLY ONE PRODUCT to give a result which is normally obtained by using at least three different types of chemical (coagulants, floaters, pH regulators, antifoams, etc.), and to provide technical support to our customers after sales.

All products in this field are developed with a conscious to meet our customers’ needs with minimum cost and maximum performance.